| Melting /Casting Our production process begins with the process of metal melting. Utilizing the properties of aluminum as a highly recyclable metal, we manufacture aluminum alloys with different material components from raw metal, or scrap, etc. After melting in the furnace with latest technology, chemical compositions of aluminum are adjusted and processed and we supply various aluminum alloys on every melting charge. In addition, hydrogen gas and inclusions mixed in molten metal are also removed with each equipment in-line. This is a system that helps our company to provide customers with various aluminum alloys, offer high quality and can be delivered on time, in accordance with customer requirements. |

| Extruding The extrusion process is a hot fabricating aluminum or aluminum alloy at a temperature of about 400 ~ 500 ℃. Typically, using hydraulic extrusion press, cylindrical ingots are pressed and extruded to the shapes through dies. By this method, our extrusion process produces hollow products as well as complicated cross-cutting products that are difficult to process by other methods. We may also manufacture products with extremely precise shapes and sizes. |

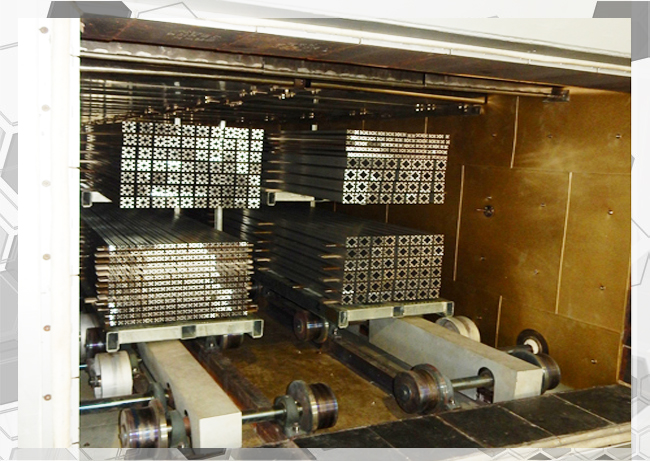

| Heat treatment Aluminum alloy is extruded and then tempered to improve its mechanical strength before being delivered to customers. In addition, when customers need to bend products, special heat treatment technology is used, providing products in a state that helps customers. |

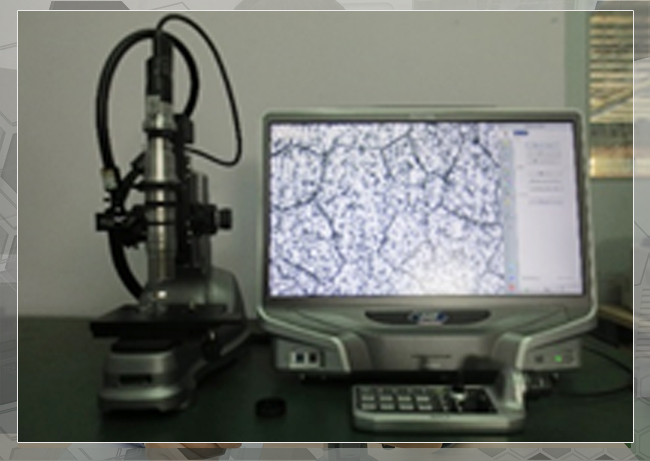

| Inspection We have a quality management department to ensure that manufactured products meet our customers’ technical requirements. We always check to make sure that the product meets mechanical strength requirements and that the chemical composition is within the permitted range and that the size and shape of the product is in accordance with the drawing, ensuring that it is correct according to the production specifications. In addition, we also monitor the organization and operation effectively to assess whether the product quality is satisfactory or not, which may involve proposing materials suitable for the intended use of the customer. |

| High Precision Cutting We may supply products with severe tolerance with cutting length from 50 to 6,000 mm. |